| Machining | Pulley Assembly | Hardware Install | Sensor Wiring | Software Setup |

Machining

Here is the procedure to machine your own pulley, if you choose to do it yourself. The overall process is the same for both aluminum and steel pulleys. If it looks to intimidating you can always send it in for us to complete for you.

Tools you'll need:

9" Lathe - Or a friend with one..

8" calipers

Dial test indicator

2 x Mag Base for X and Y

2" dial indicator (optional for cut depth)

1" dial indicator

1-2-3 blocks

Pencil / Pen

Some paper

About an hour

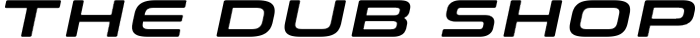

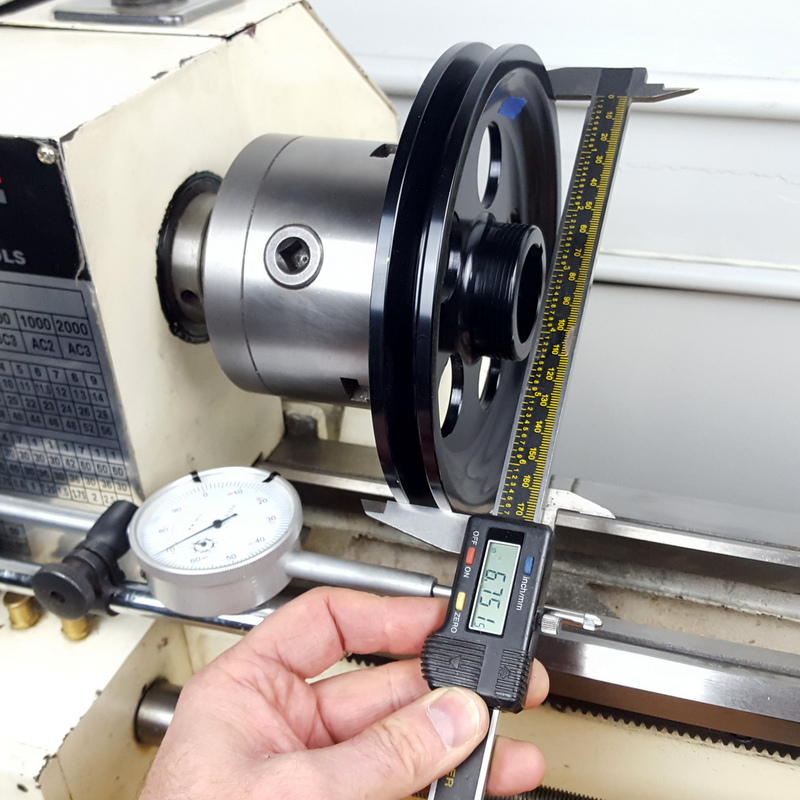

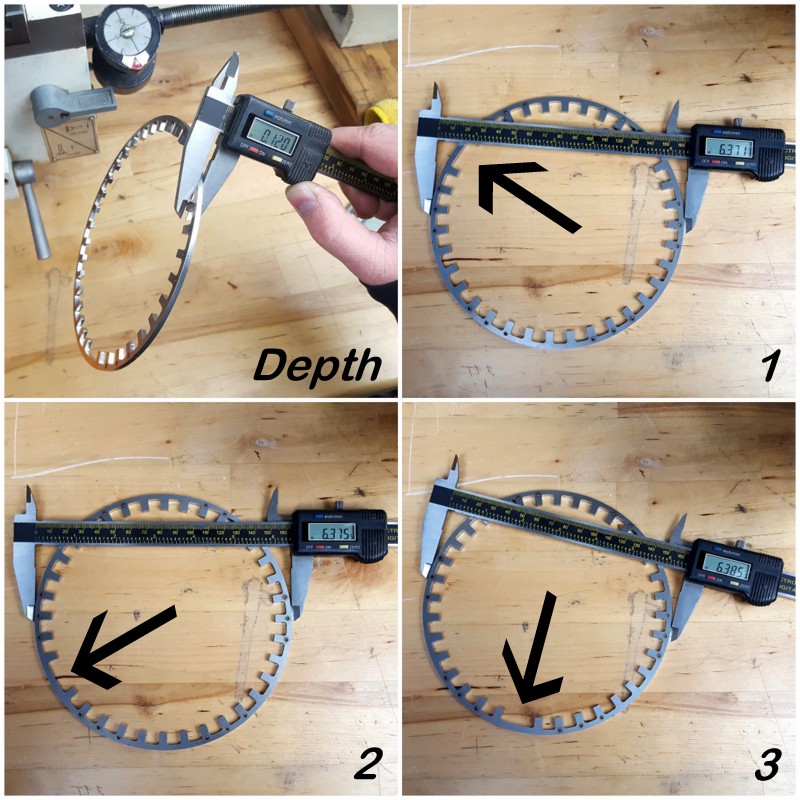

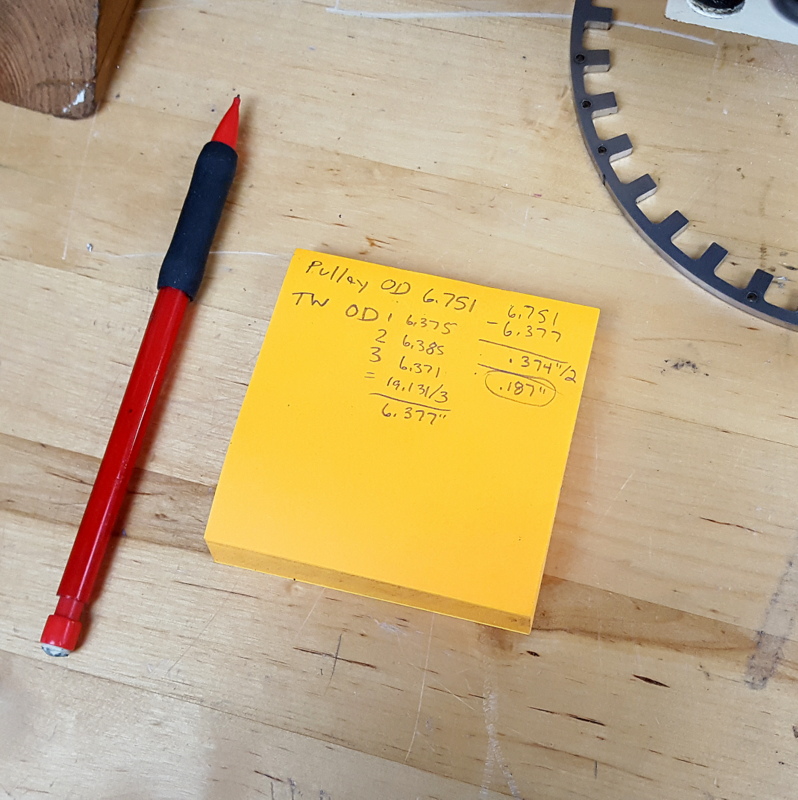

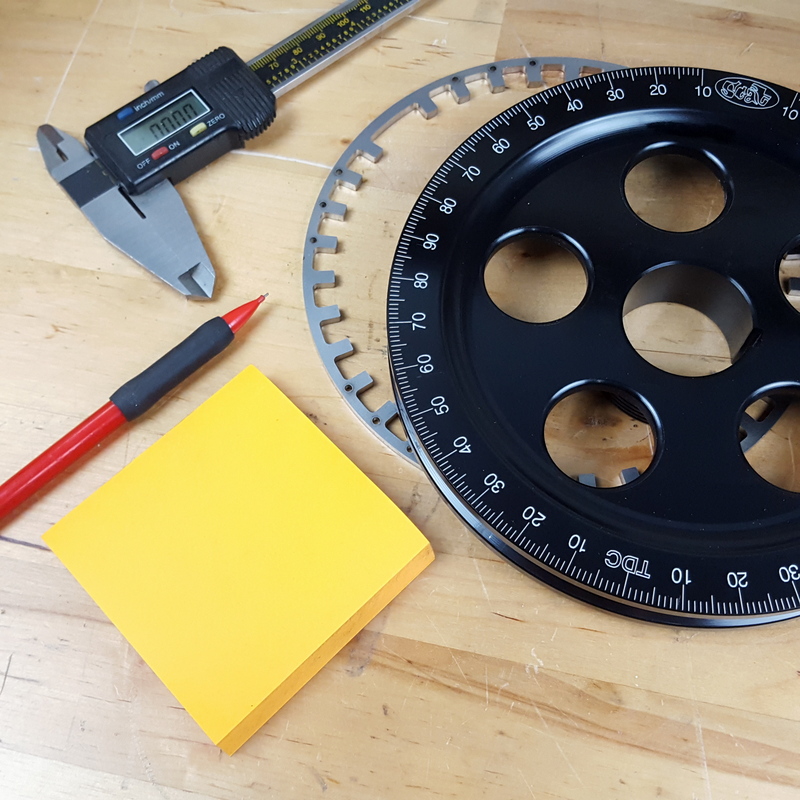

You will need have your pulley with trigger wheel, a note pad, pencil and some 8" calipers. |

||

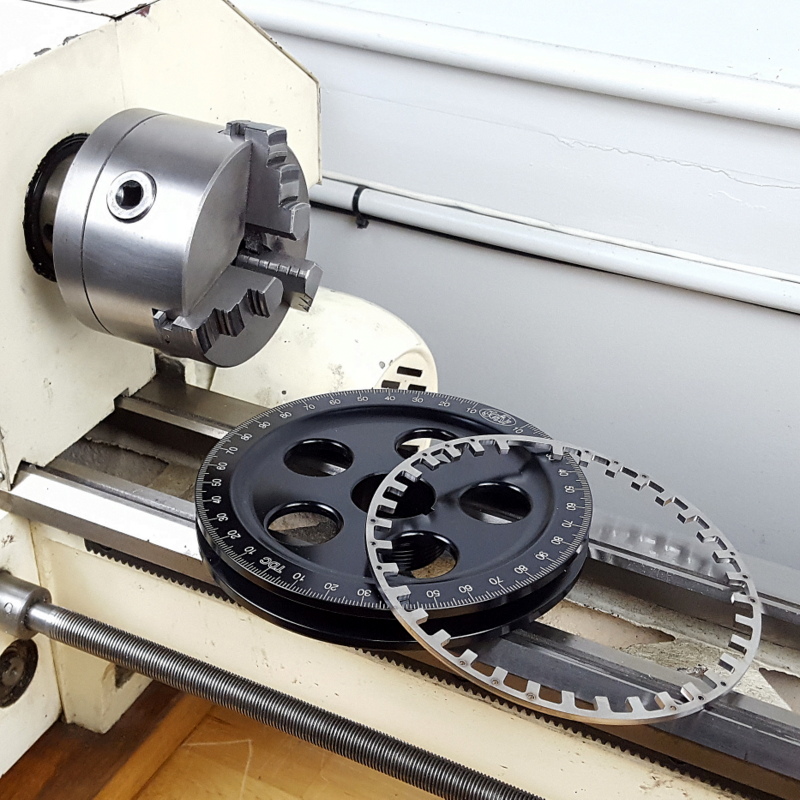

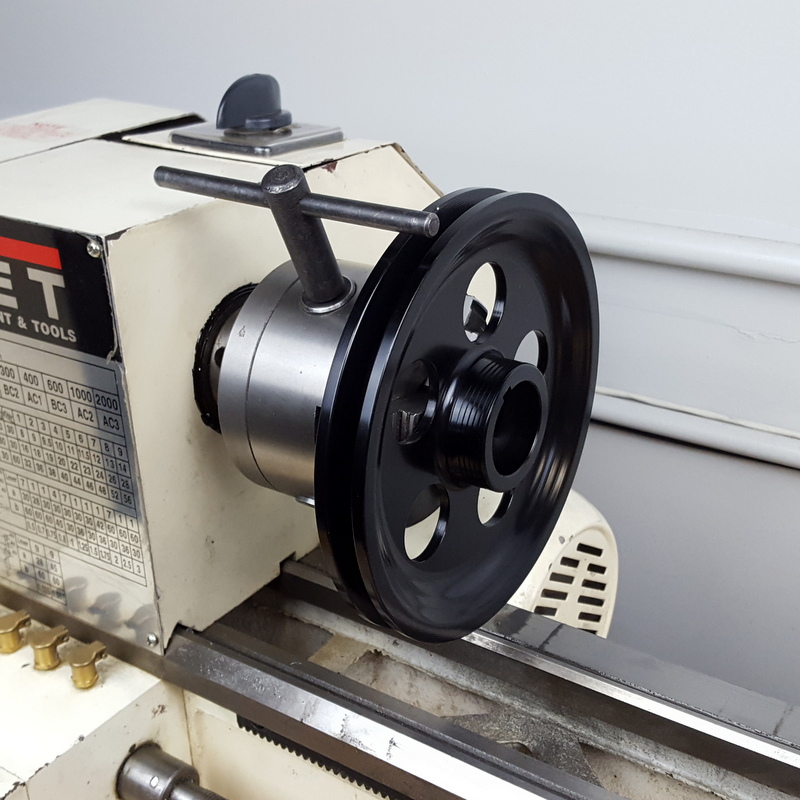

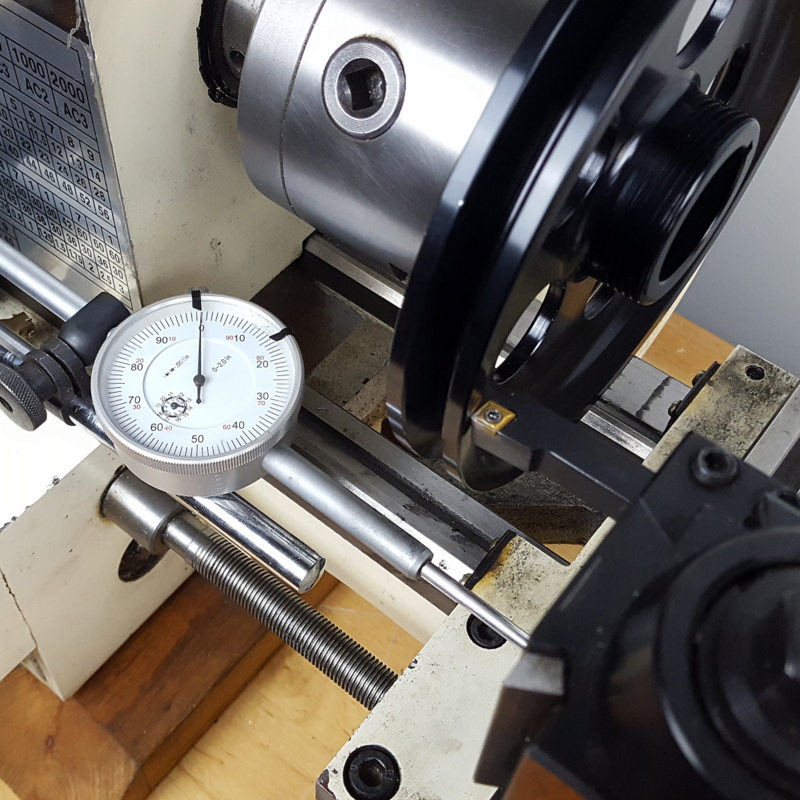

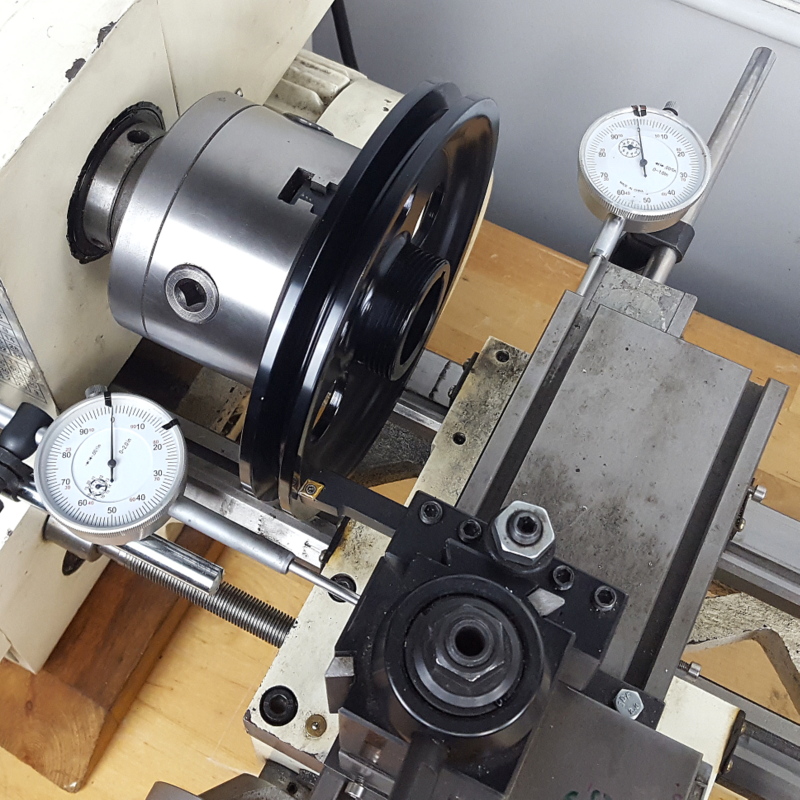

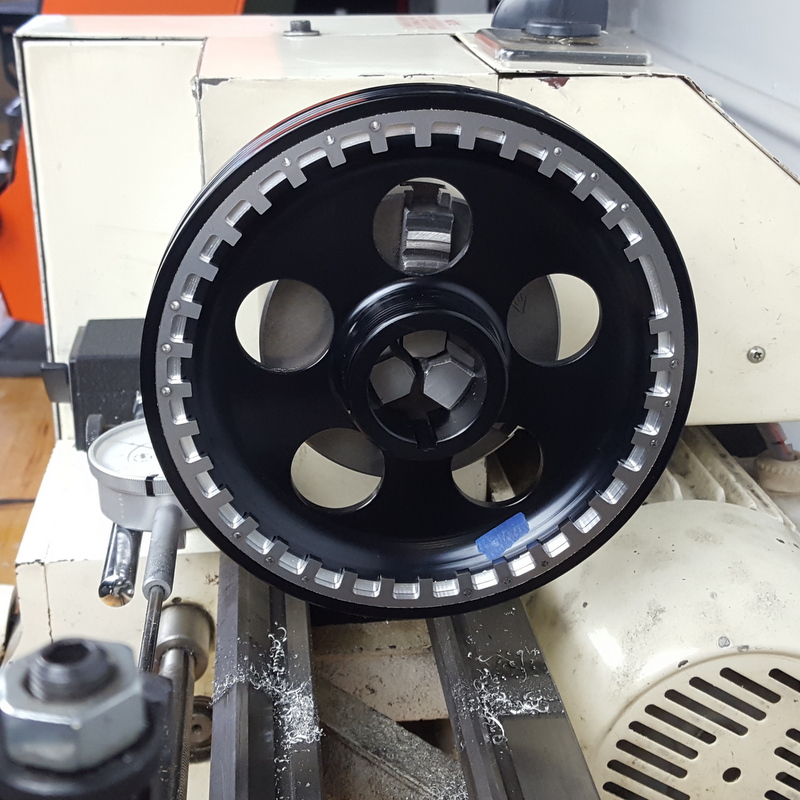

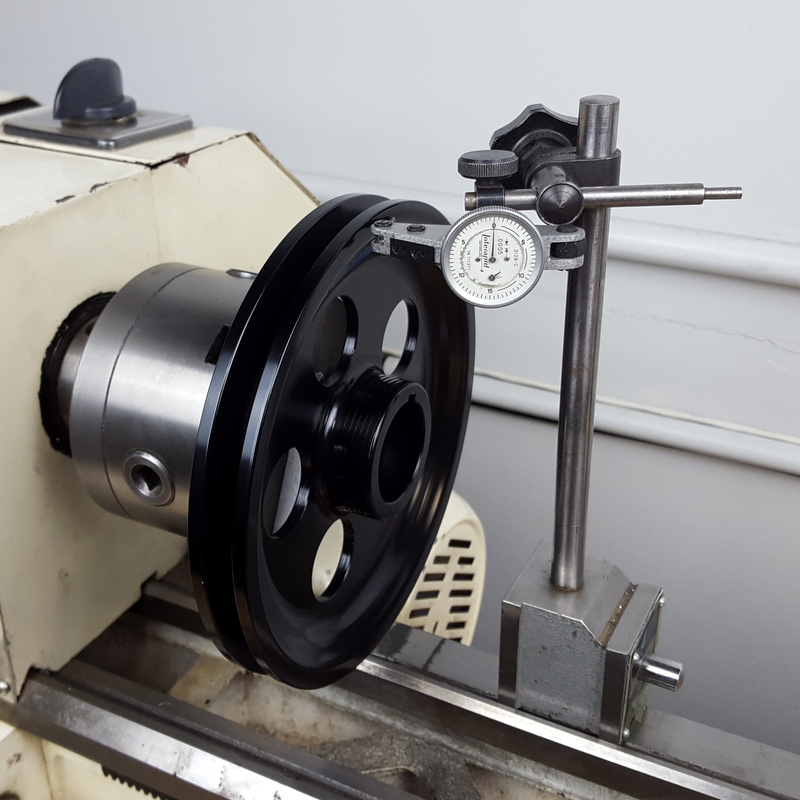

Once your pulley is secure and you have removed the chuck key you can now start to zero in your pulley as shown with a dial test indicator with a resolution of at least .0005". Here is an inexpensive one if you are looking to buy one - https://amzn.to/2YMUbuT |

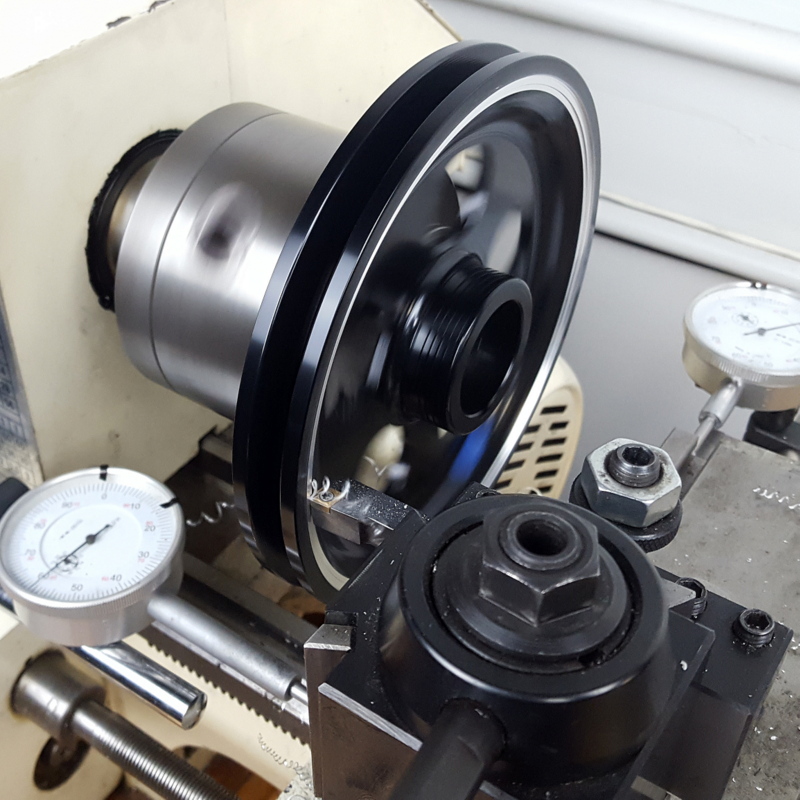

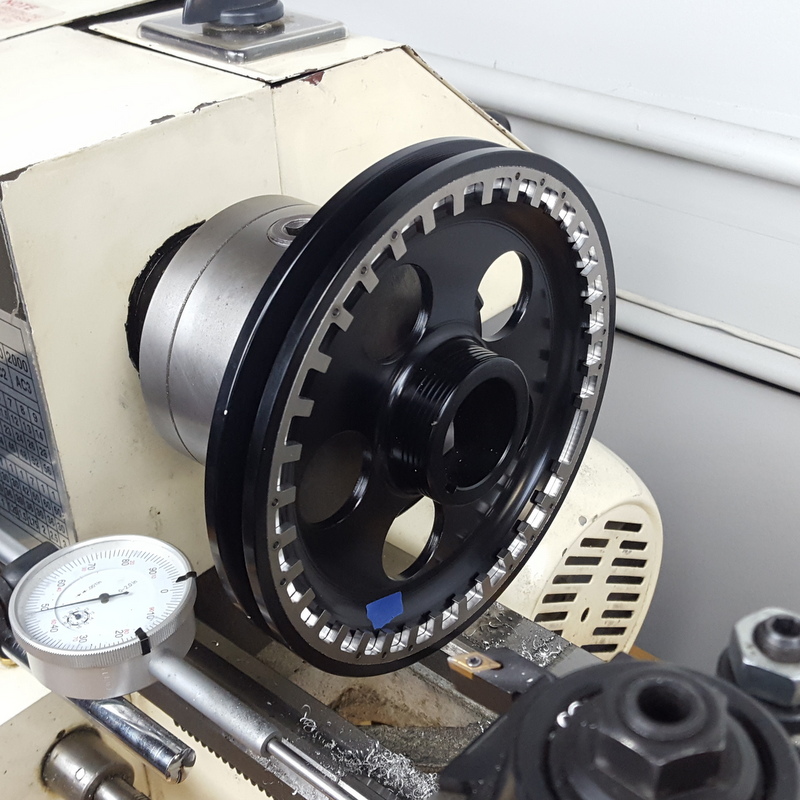

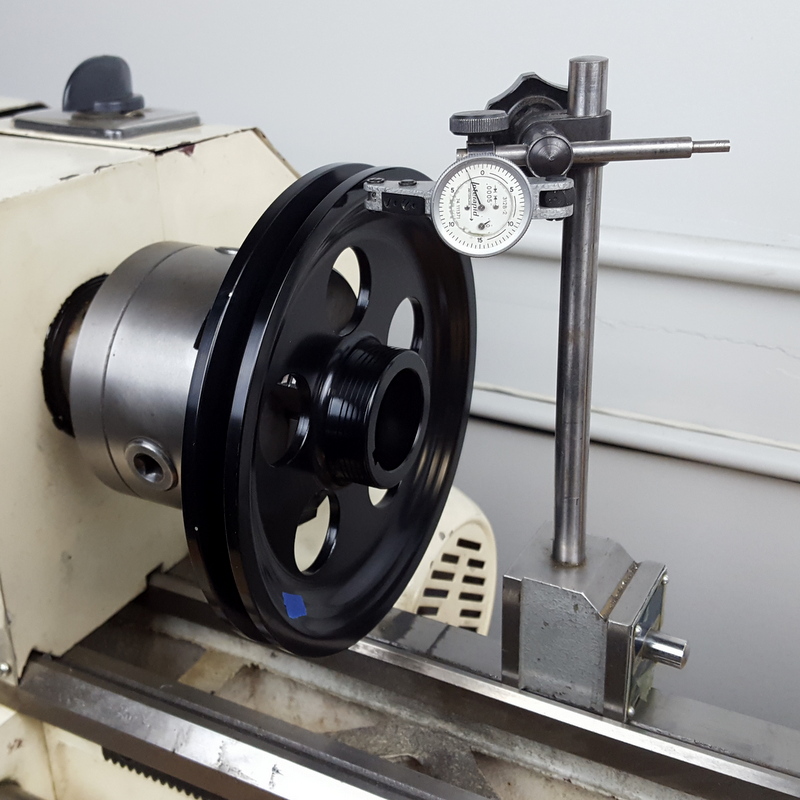

You will want to rotate the pulley manually and find the low spot. Here we are about .002" from true. Softly tap the face of the pulley to bring this to zero. With premium pulleys it is easy to achieve a tolerance of +/- .0005". Some pulley types will only dial into +/- .0015", don't worry it isn't the end of the world. Continue on. |

|

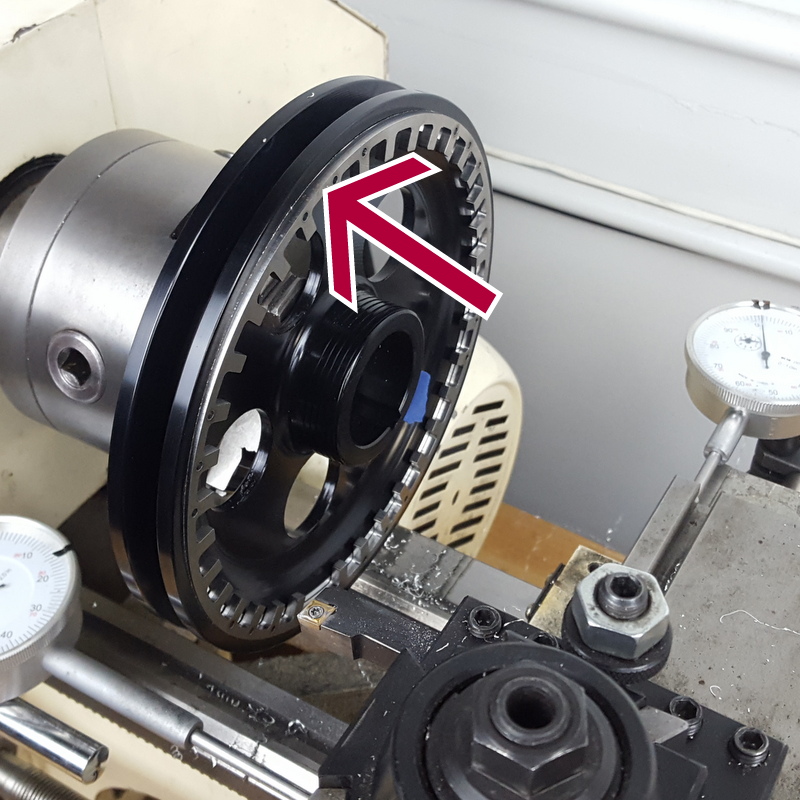

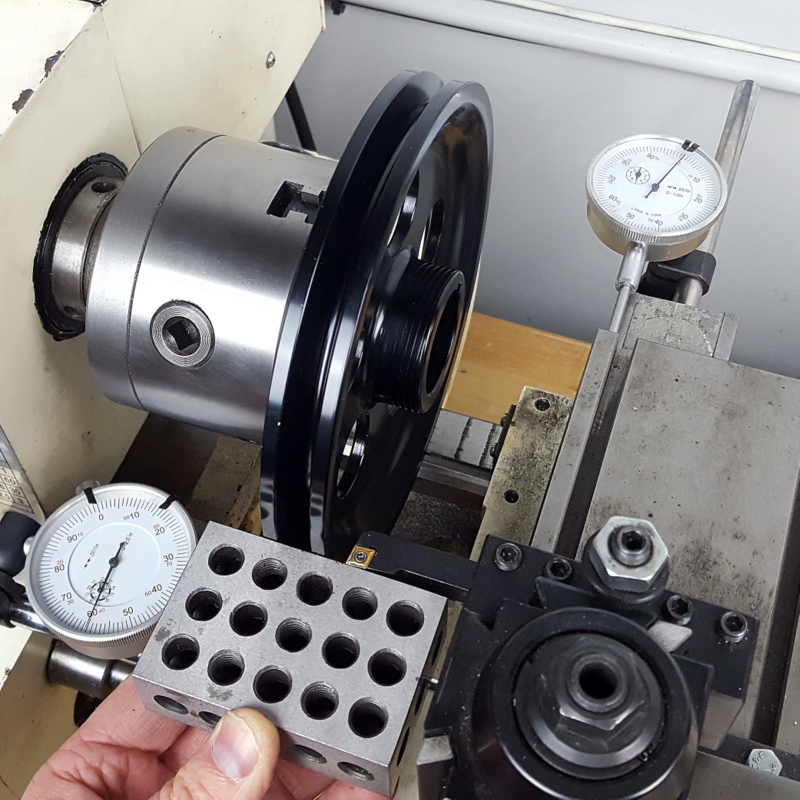

I then use a 1-2-3 block to find the outside edge and use this as a tooling reference. |

||

Pulley Assembly

Click on your pulley type below, or scroll down to the appropriate section:

Aluminum Pulley

Tools you'll need:

Drill Press

#4-40 Tap and #43 Pilot Drill

7/64" Drill Bit

#4 Countersink

Blue Loctite

Sharpie

30-45 minutes

Steel Pulley

|

Step #2 Transfer the mark down the side and onto the backside of the pulley. |

||

|

Step #4 Once you mark the pulley and the trigger wheel, install the wheel by lining up the marks.

|

Step #5 The next step is to mark the pulley at 45 degree increments around the pulley.

|

|

|

Step #9 Get out your tig and filler rod. I use ~75 amps and 1/16" filler. |

||

|

Step #10 Clamp the pulley/trigger wheel combo to the bench and get ready to weld.

|

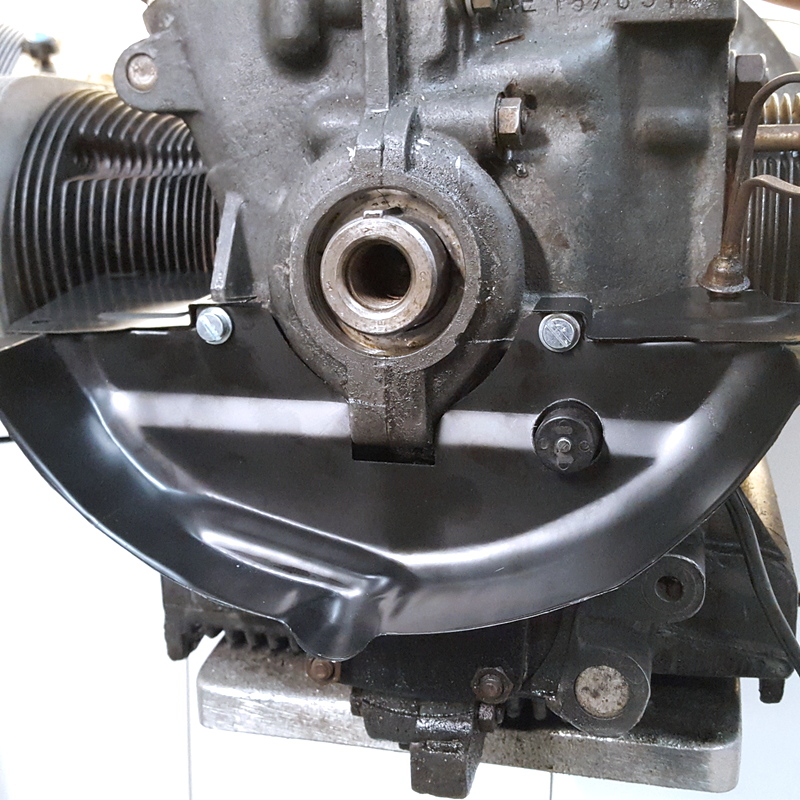

Hardware Installation

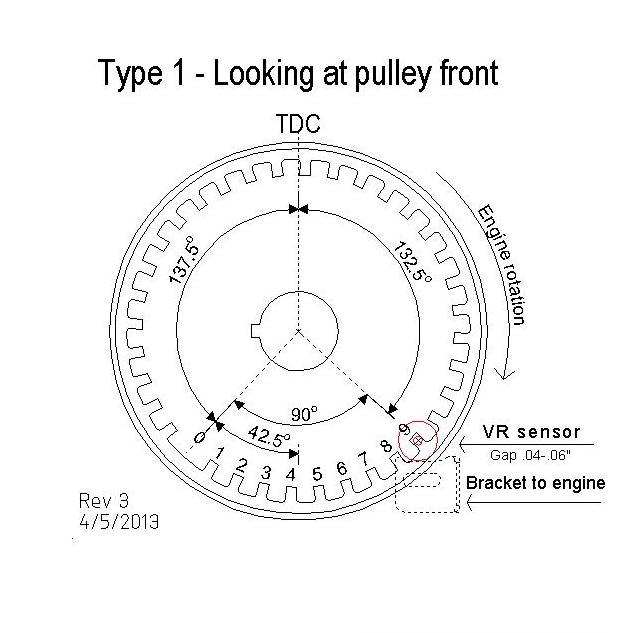

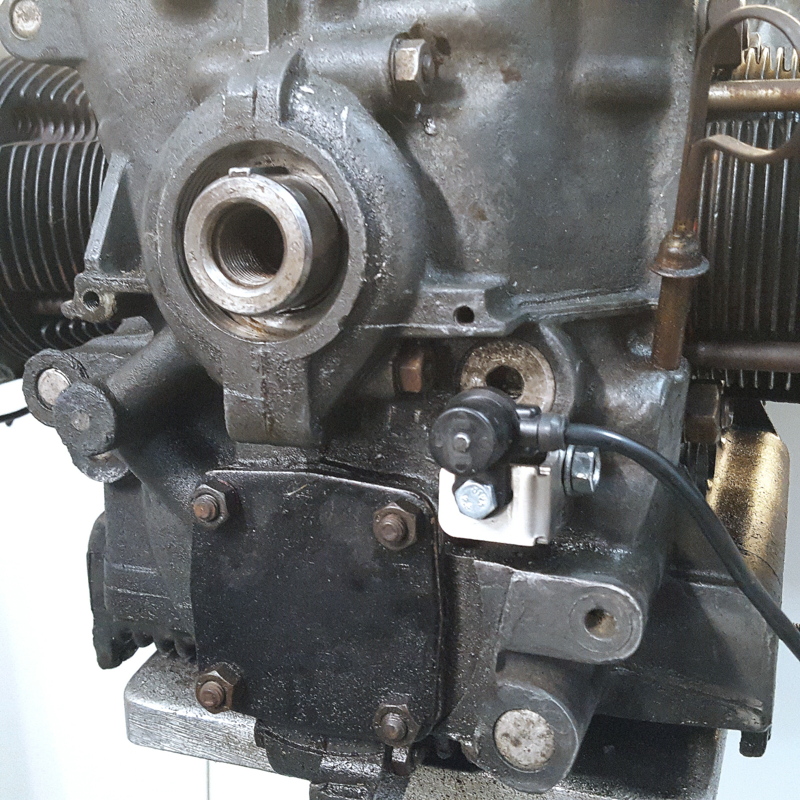

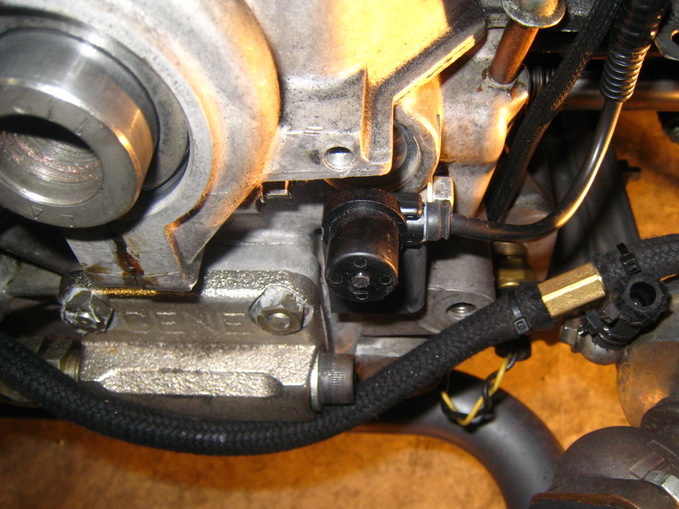

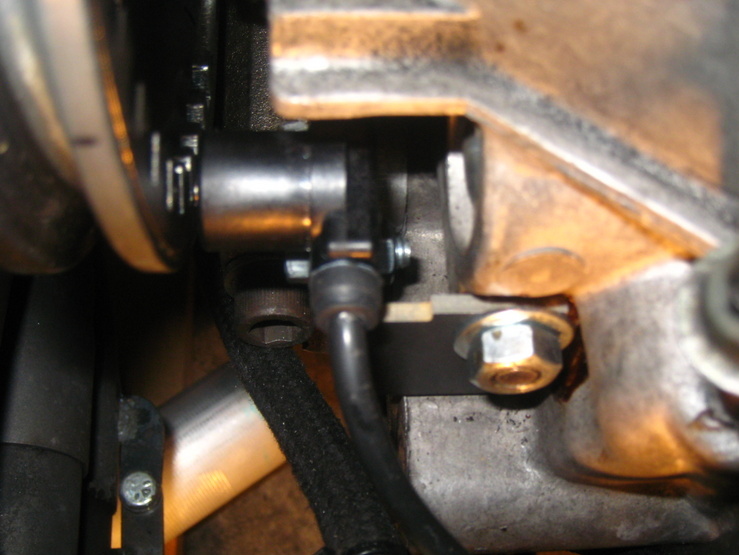

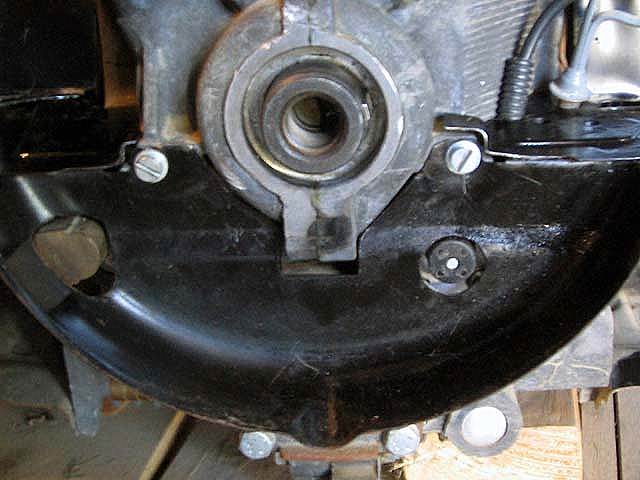

On a Type 1 engine, the crank sensor will be placed behind the pulley to the right of the oil pump attached to the case bolt. You must put a hole in the Tin for the sensor to poke through.

With some aftermarket Crankcase's the bracket will need to be clearances for proper fitment. Optionally an additional washer could be placed under the bracket to bring it off the case slightly. The brackets are designed to have enough adjustability to compensate for this. You may mount the sensor on the front or back side of the mounting bracket. This is to allow for almost any case/pulley combo.

If you are installing a Bergmann pulley combo, the sensor itself may need to be trimmed slightly to sit tightly against the case. Usually less than 1/8".

When using a Dry Sump pulley, the trigger wheel must be machined for at least 1/2 the thickness of the trigger wheel to prevent clearance issues with the oil pump. You may need to add pulley spacers to gain this clearance. Once you install your new pulley be sure to check the belt alignment and shim the pulley and or alternator pulley to prevent abnormal wear.

|

|

|

|

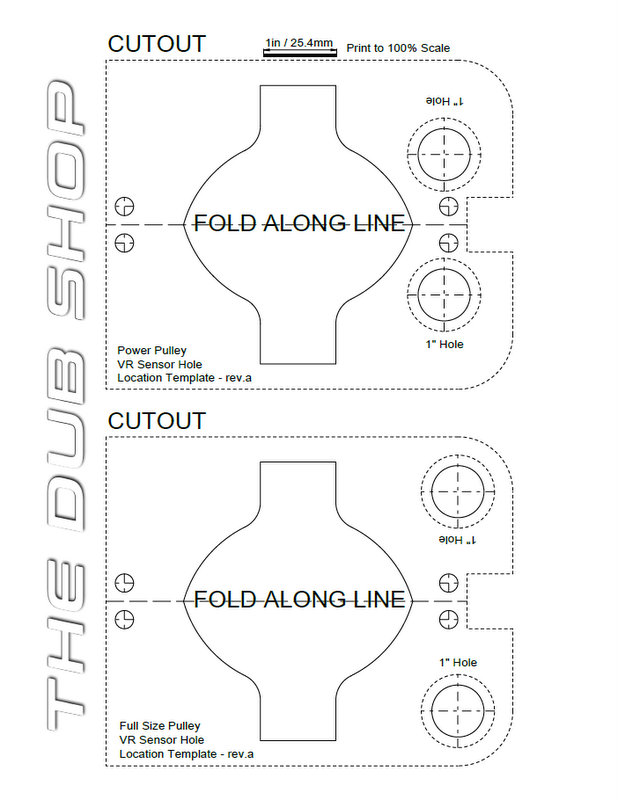

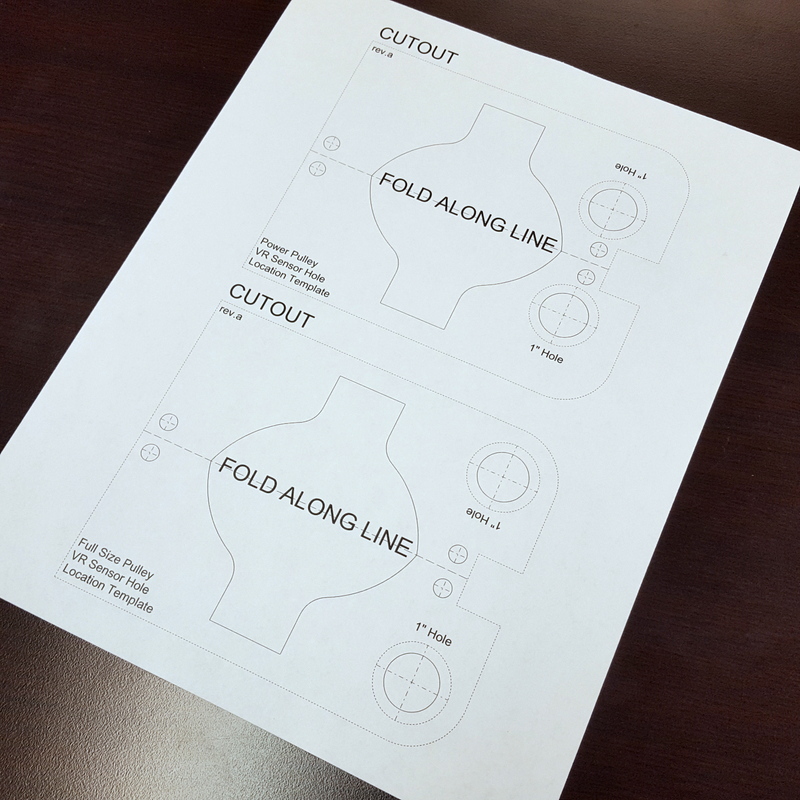

* Print this template * |

Mount sensor |

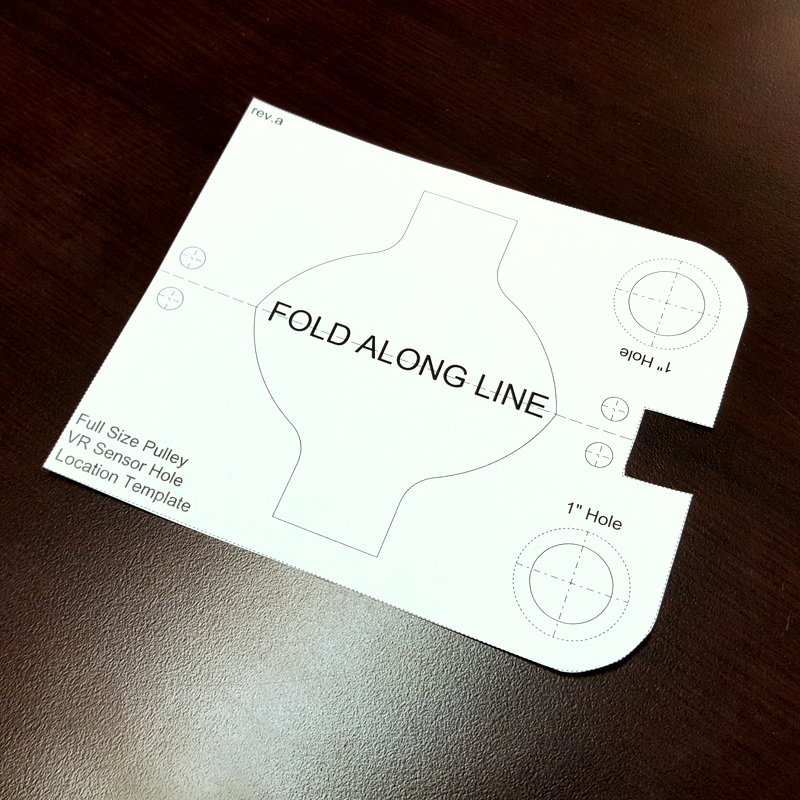

Print template |

|

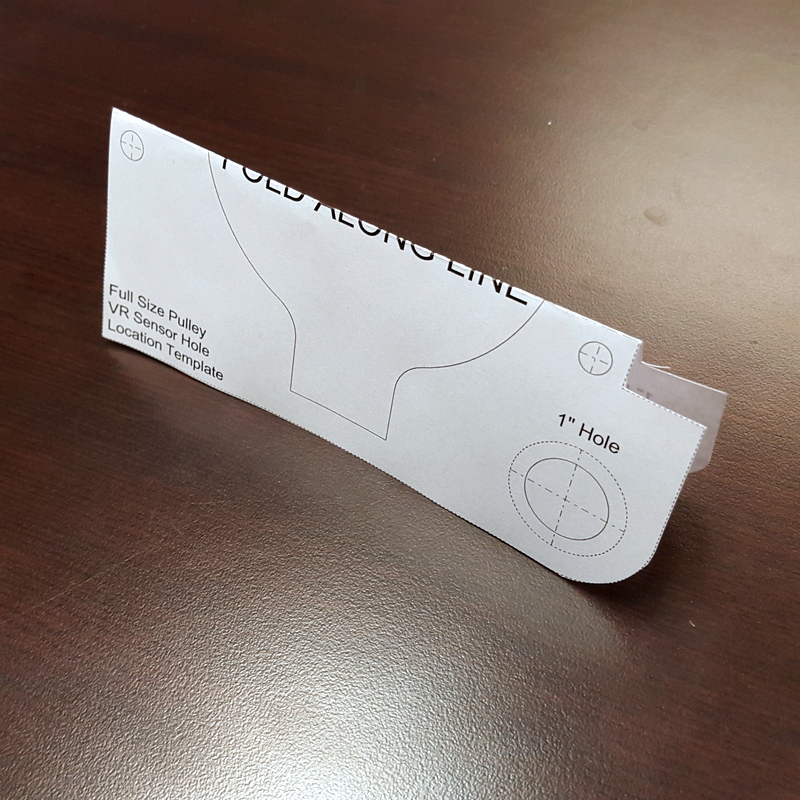

Fold template in half |

||

|

Now tape front side |

Prepare for 1/8" pilot hole |

Pilot hole drilled |

|

Enlarge Pilot with hole-saw or Uni-bit |

Place tin to check fitment |

You will want to keep the hole slightly oversize to allow for sensor adjustment when the pulley is installed |

Indexing Your Trigger Wheel

With dozens of pulley options, multiple trigger wheel sizes and different crank sensor brackets, there are multiple options for installing the trigger wheel.

The 42.5 Degree angle referred to in the illustration above represents the missing tooth position BBDC (Before Bottom Dead Center). While viewing the pulley from the front this is at the 6-9 o'clock position and from the back the 3-6 o'clock position. My standard pulley is a CB Performance Santana Pulley. They are a high quality part with engraved timing marks. Pulleys with silk screened timing marks tend to rub off in a short period of time. 90 degrees is a standard sensor to missing tooth offset between ECU manufacturers. This puts the sensor at position "X" and the missing tooth 90 degrees ahead of it. The next tooth on the trigger wheel is the #1 tooth. This is known as the #1 tooth angle. Making my standard #1 tooth angle 80 degrees with a rising edge trigger.

42.5° BBDC - 6.5 - 7" Pulleys

35.5° BBDC - Power Pulleys

32.5° BBDC - Dry Sump or Bergmann Pulleys

Typical Sensor Gap - .030"

CB Performance products specifically the preferred #1 tooth angle is 70 degrees instead of 80. This moves the missing tooth 10 degrees closer to BDC on the pulley. So when using a CB Performance controller you will use the following missing tooth position.

32.5° BBDC - 6.5 - 7" Pulleys

25.5° BBDC - Power Pulleys

22.5° BBDC - Dry Sump or Bergmann Pulleys

Typical Sensor Gap - .030"

Sensor Wiring

MS2 Sensor WiringSensor / ECU

Red - VR+

Green - VR- Black - Shield |

MicrosquirtSensor / ECU

Red to VR-

Green to VR+ Black - Shield (can be left open/disconnected) 10k shunt resistor added across VR+/VR-

|

CB Performance Magna ProductsSensor / ECU

Red to VR- (Black)

Green to VR+ (Clear or White) Black - Shield (can be left open/disconnected) Holley Terminator XSensor / ECU

Sensor Red to A30 (Crank Speed Input)

Sensor Green to A14 (Cam/Crank Ground)

(If for some reason there is still no RPM signal, swap these to reverse the polarity) Sensor Black to A18 (if you wish to connect it, usually not necessary.) |

Fuel Tech 450/550Sensor / ECU Fuel Tech 600Sensor / ECU |

*IMPORTANT NOTE*

Recently we have received crank sensors (in late 2024 into 2025) with alternate wire colors. In most cases the Green wire has changed to White. Everything is the same, the color is just different. All the above sensor wires can be exchanged with these new colors if your sensor differs from the above.

White - VR-

Black - Shield

Software Settings

For Megasquirt 2, Megasquirt 3, and Microsquirt installations use these base ignition settings with my crank trigger packages:

#1 Tooth Angle 80°

Rising Edge

Once the installation is complete you will want to verify timing with a timing light. If the computer readout does not match the timing light adjust the #1 tooth angle to get the two to match. This is very important.