If you have purchased an EFI package from me, please email for the most up to date PDF version. This page is only a general guide

Check for Leaks

If your Megasquirt is installed correctly, when you turn the ignition on you should hear your fuel system prime. It is very important to check for fuel system leaks at this time. You could find anything from a drip to a stream of fuel. It is extremely important to fix these leaks before proceeding. Take caution when fixing leaks as pressurized fuel could spray out. Cycling the key a few times when you believe the system is tight would be a good idea. A few fuel pump priming pulses should be a good test before getting the car running. If you have a pressure gauge on your regulator you can do a quick pressure check. This will get a final adjustment once your vehicle is running. But you should see around 40 psi at this point.

Connect to Megasquirt ECU

Install TunerStudio on your laptop. Then connect the serial port from Megasquirt to your laptop's USB port using the supplied tuning cable. At this point, follow the instructions in the Megasquirt manual to finish connecting. You can find the instructions for this in section 2.10 of the Setup Manual linked below. You may need to install drivers for your new serial to USB tuning cable. They are in the small disk provided with the adapter. Should you not have a CD drive on your computer, here is a link to the drivers so you can download them directly by choosing the link associated with your operating system - FTDI Serial Drivers

Sensors Calibration

Some sensors will need calibration before startup

TPS - 'Tools → Calibrate TPS'

- With your foot completely off the throttle, press the 'Closed throttle ADC count' button, then

- With the throttle opened all the way, press the 'Full throttle ADC count' button, and

- Click on the 'Accept' button.

Wideband 02 - 'Tools → Calibrate AFR Table'

- If you purchased a complete EFI package from The Dub Shop, this has already been done. See Step 4

- Select your EGO sensor from the dropdown menu (my packages use Innovate LC1 / LC2 Default)

- Click on the 'Write to Controller' button.

- Next you will need to setup the wideband controller

You can find the manual for your Innovate LC-2 here. What you need to do first is a "free air" calibration. This is outlined on pages 5 and 6. Next you will need to configure "Analog Out 2" to match "Analog Out 1". Follow the instructions on pages 7 and 8, this will be done through LM Programmer program that came on the disc with your wideband. The disk that came with your wideband kit. If for some reason the disk was not included, or it had gotten lost you can find the program here - https://www.innovatemotorsports.com/support/downloads/LogWorks3Setup.exe

Checking Sensors

Go through your dashboard and make sure sensors are reading correct values. If the specific sensor is not shown on the dashboard, you can add it by right clicking on the dashboard and adding a gauge. If you are using the unregistered Lite version, these will reset to the default gauges upon exiting TunerStudio. Your intake air temperature should be reading close to ambient temperature as well as the coolant temperature. TPS should sweep from 0 to 100% smoothly. If any sensor is not reading correctly, check that you have it wired properly. Sometimes a bad ground can cause sensors to read strange values. Start by wiggling the wires at the relay board to see if one of the screw terminals didn't get tightened.

Crank Trigger Setup

You must also make sure that the timing is synchronized between the engine and the ECU. If you haven't already, check the trigger offset for your trigger wheel. For most installations the #1 Tooth Angle to 80 degrees. This can be found within the ignition settings page of TunerStudio under 'Ignition Options / Wheel Decoder'. If you have purchased a complete EFI package from The Dub Shop this will have already been done. But double checking isn't a bad thing.

| Sensor Type | VR | Hall |

| Spark Mode (Dizzy,EDIS,wheel) | Toothed Wheel | Toothed Wheel |

| Ignition Input Capture | Rising Edge | Falling Edge |

| Number of Coils | Wasted Spark | Wasted Spark |

| Spark A | D14 | D14 |

| Trigger Wheel Arangment | Single Wheel w/ Missing Tooth | Single Wheel w/ Missing Tooth |

| Trigger Wheel Teeth (teeth) | 36 | 36 |

| Missing Teeth (teeth) | 1 | 1 |

| Tooth #1 Angle (deg BTDC) | 80 | 80 |

Check for RPM

Now that you have gotten most of the setup complete you need to check for a crank signal before you go any further. This is pretty straight forward. Make sure your fuel pump/coil is disconnected or the fuse pulled. Have TunerStudio open with your ECU connected and while cranking the engine watch the engine speed gauge in the top left corner. This should register ~250 rpms as you crank. Also the Sync Loss counter in the lower right hand corner should not count up.

- If the rpm does not register check the sensor gap is not to large or that the wiring is not connected backwards.

- If the Sync Loss counter is going up verify the sensor is not touching the trigger wheel while cranking

Verifying Base Timing

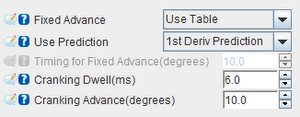

Now we have RPM so we can check timing. Set your "Cranking Advance(degrees)" to 10° in the ignition settings menu.

It should look similar to this and in the top right corner (MS2/3 variants).

Have a friend crank the car while you check the pulley with a timing light. The timing light should hit on 10° precisely. If not make small adjustments to the #1 Tooth Angle. If timing is retarded (8° on pulley) Lower #1 tooth angle. If you are advanced (12° at the pulley) Raise #1 Tooth angle until the timing on the crank matches 10 degrees while cranking. It should already be fairly close, if not dead on. Make sure to reset the timing from 'Fixed timing' to 'Use Table' once the initial timing has been verified.

Ready to Run?

If at this point everything seems correct, reinstall your fuses and connect anything else you may have disconnected, check for oil pressure, fuel pressure, and no leaks, go ahead and start the car!

Once the car is running you will need to verify fuel pressure is 43.5psi (I use 45psi it's easier to remember) with the car running and the vaccum/boost reference disconnected.

After that is competed do a running timing check as outlined in section 2.22 of the setup manual.

Now you can move to the fun part section 3, tuning the engine!